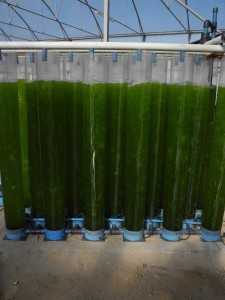

- Microalgae cultivation and recovery in photo-bioreactors;

- Beneficiation and upgrading of discarded coal and coal fines using the microalgae biomass.

- Conversion of the coal-microalgae composites (Coalgae™) into energy products such as bio-crude oil, synthetic gas and clean coal.

Advantages

Coalgae™ is a biomass-rich fuel made from a waste product that can be used as a direct replacement

for coal. The microalgae allows selective recovery of coal fines from mineral contaminants in the waste coal, thus providing a cleaner and upgraded coal product.

The microalgae cultivation system developed is cost comparable to open pond raceways, but has lower water losses and greater microalgae yields (0.6g/L dry mass). The carbon dioxide and micronutrients required for microalgae cultivation can be sourced from flue gas emissions produced by coal-fired power stations and other industries, thus reducing point source carbon emissions.

Progress

Coalgae™ is the first market-ready product of the technology. The production technology has been demonstrated over three years on a pilot plant at the NMMU capable of producing 5 tons of Coalgae™ per annum. A micro-demonstration plant is being built to produce 20 tons of Coalgae™ per annum. A basic engineering study for a 1 hectare demonstration plant has been completed by Hatch-Goba.

The conversion of Coalgae™ to energy products is under development at a pilot scale. The development work has shown that the conversion produces fuels that can be further refined for commercial use.

Opportunities

The technology presents the following opportunities:

Advantages

Coalgae™ is a biomass-rich fuel made from a waste product that can be used as a direct replacement

for coal. The microalgae allows selective recovery of coal fines from mineral contaminants in the waste coal, thus providing a cleaner and upgraded coal product.

The microalgae cultivation system developed is cost comparable to open pond raceways, but has lower water losses and greater microalgae yields (0.6g/L dry mass). The carbon dioxide and micronutrients required for microalgae cultivation can be sourced from flue gas emissions produced by coal-fired power stations and other industries, thus reducing point source carbon emissions.

Progress

Coalgae™ is the first market-ready product of the technology. The production technology has been demonstrated over three years on a pilot plant at the NMMU capable of producing 5 tons of Coalgae™ per annum. A micro-demonstration plant is being built to produce 20 tons of Coalgae™ per annum. A basic engineering study for a 1 hectare demonstration plant has been completed by Hatch-Goba.

The conversion of Coalgae™ to energy products is under development at a pilot scale. The development work has shown that the conversion produces fuels that can be further refined for commercial use.

Opportunities

The technology presents the following opportunities:

- Utilisation and monetisation of discard coal;

- Better environmental management of coal fines, which can reduce costs compared to alternative methods;

- Upgrading the quality of the discard coal by reducing the ash content and hence increasing the calorific value of the final product;

- Avoiding the challenges associated with co-feeding of biomass to reduce carbon emissions;

- Reduction of carbon taxes or purchase of carbon emission reduction credits;

- Incorporating renewable energy into the energy mix and improving sustainability ratings;

- Extends the life of coal mines by depleting reserves at a lower rate;

- Complies with increasingly strict environmental legislation; and

- Opens up business opportunities that are currently restricted by the carbon footprint of the customers’ processes.